China Injection Molding Procurement: Key Steps

The important meeting has recently finished, your new product is a go, the timeline is aggressive, and funding is, to put it mildly, limited. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Of course, you acknowledge. On paper, it’s logical. Savings can be substantial. However, your brain is racing with concerns. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

But here’s the catch. Procuring plastic mold needn’t be a roll of the dice. It’s simply another project with clear steps. And its outcome hinges on the approach you take. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Disregard those scary tales. Here’s a practical playbook to nail it.

Initial Step: Prepare Your Information

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You can’t expect a factory on the other side of the world to read your mind. It’s akin to asking someone to price-build “a structure” with no details. The replies will range from absurdly low to exorbitant, none of which help.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This becomes the bedrock of your sourcing project.

So, what goes in it?

Begin with 3D CAD models. These are non-negotiable. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This serves as the definitive part geometry reference.

Yet 3D models don’t cover everything. You also need detailed 2D drawings. This details critical info missing from the 3D file. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Any seal surfaces or critical hole sizes must be clearly labeled.

Then specify the material. Don’t just say “Plastic.” Even “ABS” alone is too vague. Be specific. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Don’t forget the commercial info. State your EAU. A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

The Great Supplier Hunt

With your RFQ perfected, who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. Finding suppliers is simple; finding quality ones is tough.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They let you survey dozens of suppliers quickly. But think of them as a starting point, not the finish line. Aim for a preliminary list of 10–15 potential partners.

But don’t stop there. Consider using a sourcing agent. They do cost extra. Yet top agents deliver reliable, audited suppliers. They bridge language and cultural gaps. As a newcomer, this offers priceless security. Think of it as insurance for your project timeline.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. In-person meetings trump emails. Hold samples, talk shop, and gauge professionalism firsthand. And don’t forget the oldest trick in the book: referrals. Consult trusted colleagues. A recommendation from a trusted peer is often worth its weight in gold.

Separating Real Suppliers from Pretenders

After firing off that RFQ to a broad pool, the quotes will start trickling in. Some will be shockingly low, others surprisingly high. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It’s a bit of an art and a science.

First, look at their communication. Is their turnaround swift and concise? Can they handle detailed English exchanges? But the key: do they probe your RFQ? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. It shows they’re engaged and experienced. A supplier who just says “No problem” to everything is a walking red flag.

Afterward, verify their technical arsenal. Request their machine list. Review examples of parts akin to your design. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Next up: the factory audit. This is not optional. Just as you interview hires, audit suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. That small investment can save you thousands.

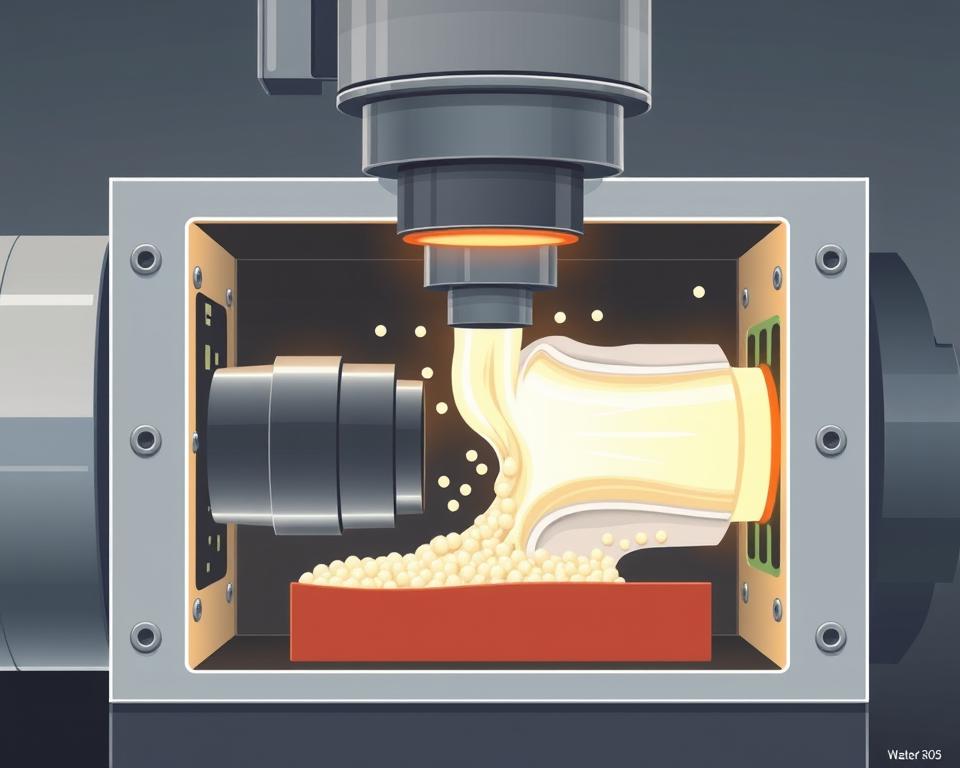

From Digital File to Physical Part

Once you’ve chosen your supplier. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the process kicks off.

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. This is your supplier’s formal feedback on your part design. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. Comprehensive DFM equals a top-tier supplier. It’s a two-way partnership. You work with their engineers to refine the design for optimal production.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These represent the first trial parts. They are your moment of truth.

T1 parts usually require adjustments. It’s par for the course. Look for small flaws, slight size errors, or surface marks. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. It could require several iterations. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Getting that golden sample feels like the end, but it isn’t. Next up: mass manufacturing. How do you maintain consistency for part 10,000?

Implement a robust QC plan. Often, you hire a pre-shipment inspection service. Use a third-party inspector again. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Don’t forget shipping details. Know your shipping terms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It relies on partnership-building. Treat them like a partner, not just a line item on a spreadsheet. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re ready.