Guide to Copper Pipe Water Line Sizes for Your Home

It may surprise you that approximately 30% of residential plumbing failures come from improper pipe sizing. Using the proper dimensions helps maintain ideal water pressure and system efficiency. This overview assists homeowners in mastering sizing fundamentals for home plumbing.

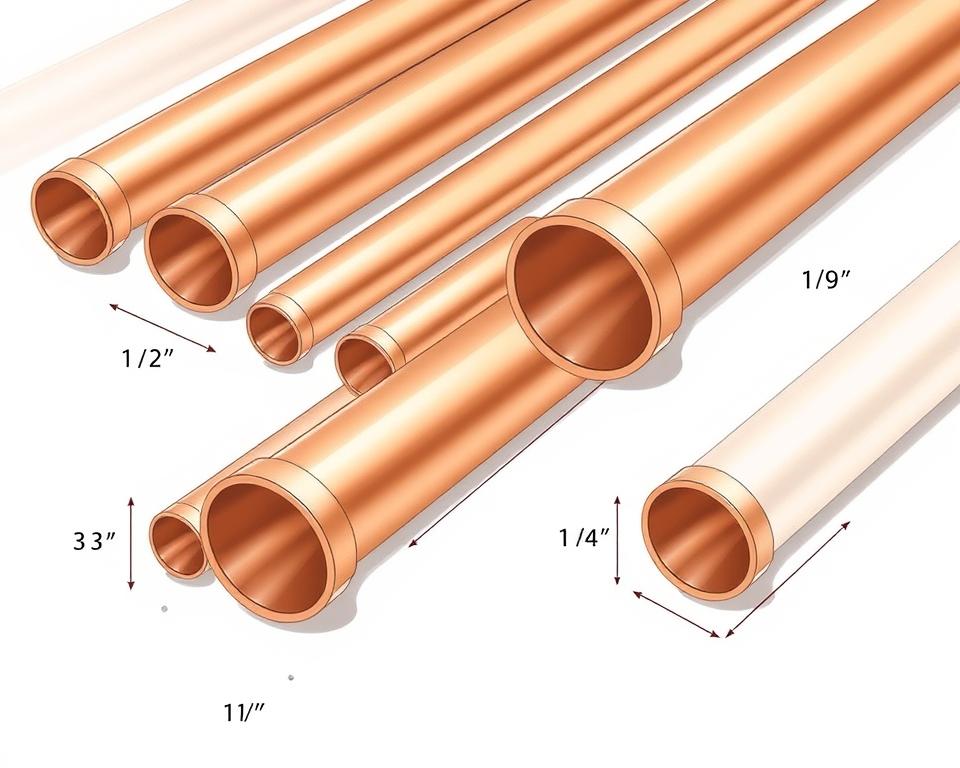

Determining the right size relies on considerations like required flow and wall measurement. Standard 3/4 copper pipe OD sizes run between 1/4″ and 8″ across, noted by NPS versus actual exterior measurements. Installation Parts Supply provides professional advice to align your home requirements with code-compliant options.

Copper remains a top choice due to its durability and corrosion resistance. Whether retrofitting your setup or installing from scratch, knowing these principles cuts downtime and avoids costly mishaps.

Key Conclusions

- Correct sizing prevents 30% of common plumbing problems

- Common sizes run between 1/4″ and 8″

- NPS measurements differ from actual outer dimensions

- Correct sizing upholds pressure and system efficiency

- Copper provides robustness and corrosion defense

- Professional guidance ensures code compliance

Reasons to Select Copper for Your Plumbing

Durable plumbing depends on material choice—copper leads the way because: Boasting a half-century lifespan and NSF potable-water approval, it’s a go-to for residences. Unlike alternatives, it combines strength with sustainability.

Longevity and Corrosion Defense

Copper naturally resists rust and chemical damage, outperforming PVC or PEX. Its smooth interior maintains water pressure by reducing friction. Practical tests confirm decades of leakless performance.

Find certified, high-grade selections at Installation Parts Supply for your requirements. Although upfront costs rise, less frequent repairs yield savings over time.

Flexibility and Freeze Protection

In frost-prone areas, its minor freeze expansion helps avert pipe bursts. This give lowers the likelihood of pricey cold-weather failures. Pair it with proper insulation for maximum freeze protection.

Sustainable and Germ-Fighting Properties

Fully recyclable, copper lessens ecological footprint. Antimicrobial action curbs bacterial proliferation to boost water purity. For eco-conscious homeowners, it’s a clear win over plastic alternatives.

Decoding Copper Pipe Dimensions and Varieties

Many homeowners struggle with pipe sizes—let’s break it down. Industry NPS labels don’t correspond to real outside measurements. For example, a 1/2″ NPS has an outer diameter of 0.625″.

Nominal vs. Actual Pipe Dimensions

NPS figures serve as tags, not precise sizes. Verify the OD itself when buying. Use this quick conversion guide:

- 1/4″ nominal → 0.375″ actual

- 1/2″ NPS = 0.625″ OD

- 3/4″ nominal → 0.875″ actual

Comparing Types L, M & K

Residential plumbing relies on three major copper types. Their wall thickness determines strength and use cases:

- Type L: Light gauge (0.040″ @ 1/2″), perfect for standard homes.

- Type M: Medium gauge (0.050″ @ 1/2″), for cost and strength balance.

- Type K: Thick-wall (0.060″ @ 1/2″), meant for high-pressure use.

Type M is suggested by Installation Parts Supply for broad residential use. Over 2″ spans usually need Type K for irrigation or business applications.

Type L Copper: Lightweight and Flexible

For homeowners tackling DIY projects, L-type offers unmatched flexibility. Its thin-wall construction reduces weight and cost while maintaining reliability. Supplied in hard lengths or bendable coils, fitting HVAC or waste lines alike.

L-Type Uses and Constraints

L-type excels in low-pressure scenarios. A 0.040″ gauge suits:

- HVAC refrigerant lines

- Drain-waste-vent (DWV) systems

- Residential water supply (below 80 PSI)

Avoid high-pressure systems—thicker-walled alternatives like Type K handle those better. Up to 50ft flexible coils hug corners, though bending must be gentle to prevent pinches.

Sizing Options and Installation Tips

Available in sizes 1/4″–8″, most often:

| Form | Max Length | Best For |

|---|---|---|

| Rigid | 20ft | Straight runs |

| Coiled | 50ft | Tight spaces |

Beginners will find rigid lengths, as recommended by Installation Parts Supply, the easiest to cut and solder. When tackling big installations, coils mean fewer joints, saving time and leak hazards.

Type M Copper Pipes: The Residential Standard

Moderate cost plus solid performance make M-type a homeowner favorite. Its medium-wall design handles everyday demands while keeping budgets in check. NSF-certified for potable water and gas lines, it’s a safe choice for kitchens, bathrooms, and heating systems.

M-Type Best Applications

Perfect for mixed hot/cold service, keeping water pressure uniform. Rigid 12ft lengths suit straight runs, while 100ft coils adapt to tight spaces. Popular applications are:

- Drinking water distribution

- Medical gas lines (oxygen, nitrous oxide)

- HVAC refrigerant lines

Wall Thickness and Pressure Tolerance

It balances the characteristics of L and K. With 0.050″ walls, it tolerates up to 150 PSI without failure. See the specs contrast:

| Type | Wall Thickness (1/2″) | Max Pressure | Best For |

|---|---|---|---|

| L | 0.040″ | 80 PSI | Low-pressure DWV |

| M | 0.050″ | 150 PSI | Residential supply |

| K | 0.060″ | 200 PSI | Irrigation |

Find M-type in every common size at Installation Parts Supply. Combine with proper flare connectors for gas lines to secure seals. Include minimal expansion spacing in hot piping for thermal growth.

Type K Copper for Tough Applications

For ultimate robustness, choose K-type in rigorous settings. Its thick walls and high pressure tolerance make it ideal for industrial and underground use. Unlike thinner alternatives, it resists crushing and corrosion in harsh environments.

K-Type for High PSI & Irrigation

K-type excels where others fail. Its 0.060″ wall thickness (for 1/2″ NPS) handles up to 200 PSI, perfect for:

- Underground irrigation systems

- Commercial HVAC refrigerant lines

- Fire sprinkler networks

For buried lines, Installation Parts Supply recommends 18″ minimum depth. Pair with compression fittings torqued to 25 ft-lbs to prevent leaks.

Rigid vs. Coil: Installation Advice

Choose the right form for your project. Use 12ft rigid lengths for straight lines; 50ft coils for curves. Compare performance:

| Form | Best For | Limitations |

|---|---|---|

| Rigid | High-pressure mains | Requires more fittings |

| Coiled | Trenchless installations | Risk of kinks if bent sharply |

Plan irrigation loops with 10% extra length for expansion. Avoid bending rigid forms without a tube bender—kinks reduce flow efficiency.

Installing and Caring for Copper Pipes

Following best practices leads to long-lasting, leakless service. Homeowners and contractors both gain by learning these key steps. Implement these tips for reliable, enduring installations.

Permanent vs. Temporary Connection Methods

Select the joining style that fits your task. Heat or compression yield permanent bonds; non-permanent lets you tweak later. Here’s a quick comparison:

| Method | Pros | Cons | Best For |

|---|---|---|---|

| Soldering | Strong, permanent | Requires skill | Water supply lines |

| Compression | No heat needed | Bulky fittings | Tight spaces |

| Push-Fit | Quick installation | Higher cost | Emergency repairs |

How to Solder Copper Pipes

Achieve a perfect joint by doing this:

- Use emery cloth to clean both surfaces.

- Apply flux evenly to both pieces.

- Apply torch heat until you hear the flux hiss.

- Apply solder to the seam; it will wick in automatically.

Always wear heat-resistant gloves and work in a ventilated area. Lead-free solder for potable lines is available at Installation Parts Supply.

Avoiding Drips and Freeze Breaks

Use foam insulation on pipes in cold spots. Install insulating sleeves on wall-penetrating sections. Repair advice includes:

- Look for greenish corrosion at joints each year.

- Hang horizontal pipes at 32 inches intervals to avoid sag.

- Choose freeze-safe taps in winter-prone areas.

Annual inspections catch minor issues before they escalate. Keep a basic toolkit handy for quick fixes—adjustable wrenches, pipe cutters, and Teflon tape cover most scenarios.

Wrapping Up: Choosing Copper Pipes

A well-planned system lasts decades—let’s wrap up with key takeaways. Choose proper size and type for lasting durability. Keep in mind:

- Type M is best for homes; Type K for demanding uses

- Proper sizing maintains pressure and prevents leaks

- Preventing pipe freeze is vital in chilly regions

Lean on Installation Parts Supply’s expertise to make selection easy. All products are certified and backed by quality assurances for flawless plumbing systems.

Need help? Download free sizing guides or schedule a consultation today. First orders receive unique deals—kick off your job the best way!